India is one of the main producers of jaggery in the world, contributing significantly to its wealth. Jaggery is used as a traditional sweetener in a variety of dishes, most popularly chakkarai pongal which is prepared during Makara Sankranthi. It is also used in many other Hindu religious rituals.

Jaggery is usually produced by boiling sugarcane juice. However, the conventional methods to produce jaggery are of poor quality, poor hygiene, have reduced shelf life, require high amount of energy, and pollute the environment. Added to this, artificial clarificants like hydros, phosphoric acid, etc. are added to retain the golden colour of jaggery for high market value and is harmful for human consumption.

There is therefore a need for a more sustainable, efficient, and environment friendly method to produce jaggery. Several methods have been proposed to address this issue. Use of multiple heating pans, and using the waste heat present in flue gas for preheating cane juice are suggested to improve thermal efficiency. But the environmental impact of these processes can only be addressed by integrating with renewable energy technologies.

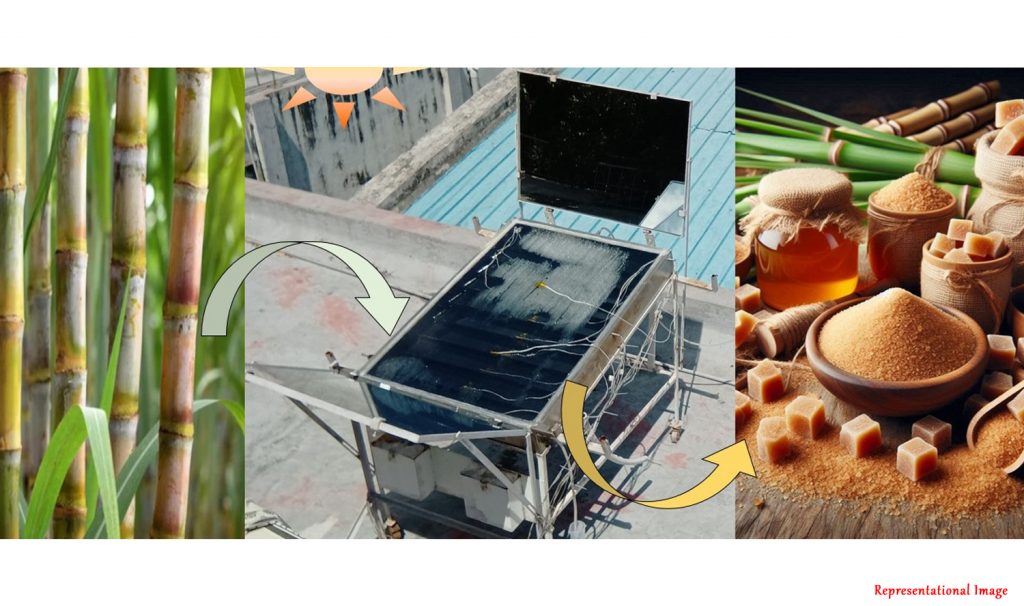

In a previous study done by the authors, a solar parabolic trough collector (PTC) powered jaggery making process was proposed. This was found to be a good solution for an environmentally friendly approach of producing jaggery. The efficiency of the system was also enhanced to a significant 51.71% by replacing the conventional heating pan with a novel heating pan.

In this study, the authors Dr. P. Venkata Sai and Prof. K. S. Reddy from the Heat Transfer and Thermal Power Laboratory, Department of Mechanical Engineering, Indian Institute of Technology (IIT) Madras, Chennai, India, have utilised an evaporation-condensation process of jaggery concentration further powered by solar PTC as a sustainable, efficient, and environmentally friendly method to produce jaggery.

The present system not only produces high-quality jaggery but also generates distilled water as a byproduct, thereby reducing the payback period. In the absence of sunlight, this distillation unit performs evaporation by flashing high pressure juice under low pressure. The process can be optimised to enhance the quality of jaggery, reduce energy consumption, and promote sustainable production practices.

In this proposed system integration, the developed mathematical model well predicts the juice concentration and distilled water productivity, which is compared with experimental results successfully. This method provides a pathway for producers to adopt more sustainable and efficient practices. This study also contributes to the broader field of food processing by demonstrating the potential of innovative technologies to transfer traditional processes and enhance the food industry.

Prof. Tapas Mallick, Professor and Chair of Clean Technologies, Renewable Energy and the lead of the Solar Energy Research Group within the Environment & Sustainability Institute, University of Exeter, Exeter, United Kingdom, acknowledged the importance of this study with the following comments: “India contributes approximately 55% of Jaggery production in the world, contributing significant benefit to Indian economy. Such production technology by the use of abundant solar energy is key to sustainable economic benefit to the country. This article uniquely provide key technological innovation for the use of low cost solar still device to use in the Jaggery production. The mathematical formulation is supported by the experimental tests provide a real condition use of such technology, which has wider benefit to the society and the environment.”

Article by Akshay Anantharaman

Click here for the original link to the paper