Graphene, often called a “wonder material,” is a single layer of carbon atoms extracted from graphite. It possesses exceptional properties, such as hardness greater than diamond, superior electrical conductivity, transparency, flexibility, and lightweight characteristics. These qualities make graphene a highly sought-after material in electronics, solar panels, bioremediation, and many other industries. However, despite its potential, the cost of production has been a major hurdle for its widespread industrial application.

To address this challenge, a team of scientists from IIT-Madras, led by Dr. Sathyan Subbiah, has developed a low-cost method for producing graphene nanoplatelets. This breakthrough could clear a significant roadblock in the application of graphene across various sectors. Traditionally, graphene is produced using either bottom-up methods like chemical vapor deposition or epitaxial growth, which yield high-quality graphene but are expensive, or top-down methods like breaking graphite, which are cheaper but result in lower-quality graphene suitable for applications like inks, coatings, and catalysts.

By exploring unconventional methods for graphene production, Dr. Subbiah and his team have made progress in scaling up the production of graphene, potentially opening doors to more cost-effective industrial use. This innovation promises to enhance the accessibility of graphene in various industries and accelerate the development of advanced technologies.

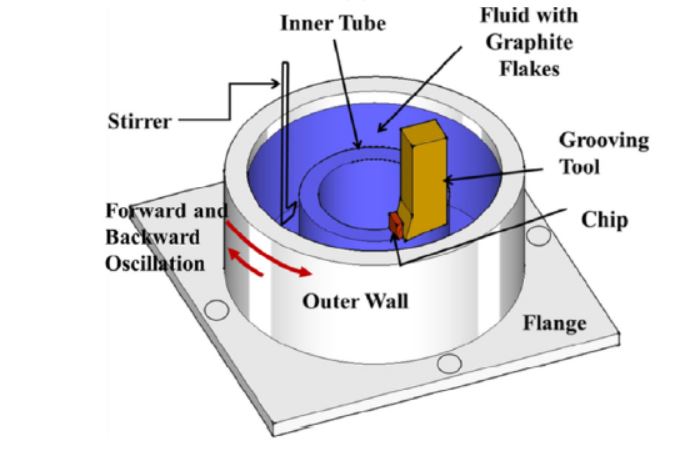

Scientists from IIT-Madras have developed an innovative method for producing graphene nanoplatelets by retrofitting an existing CNC machine to mechanically exfoliate graphite flakes. This approach leverages the lubricating properties of graphite, where graphene sheets slide easily past one another, facilitating their separation during the machining process. By doing so, the scientists were able to produce few-layer graphene, which remains suspended in a solution for various applications.

The team designed a double-tubular machine resembling a traditional flour mill. Graphite is mixed with sodium cholate, which prevents the graphene nanoplatelets from aggregating. The solution is then processed in the machine, where an inner tube with a grooving tool cuts through the graphite flakes, shearing them into smaller sizes. The machine also includes a stirrer to prevent the flakes from settling at the bottom. After running the machine for 10 hours under specific conditions, the graphite flakes are reduced to sizes ranging from 3 to 15 nanometers, significantly smaller than the width of a human hair. This process results in few-layer graphene, albeit with some defects due to the induced shearing.

The researchers plan to optimize this method to increase the yield and enhance the quality of the graphene produced. They believe this cost-effective, scalable technique could attract industrial interest for further development and application.

Prof. Ramesh Singh from IIT-Bombay, who was not involved in the study, praised the technique, highlighting its potential for commercialization due to its simplicity, low cost, and lack of specialized requirements.

from IIT Madras who developed low cost method for graphene production.

RESEARCH : https://www.sciencedirect.com/science/article/pii/S2213846318301925

Article by Aditi Jain