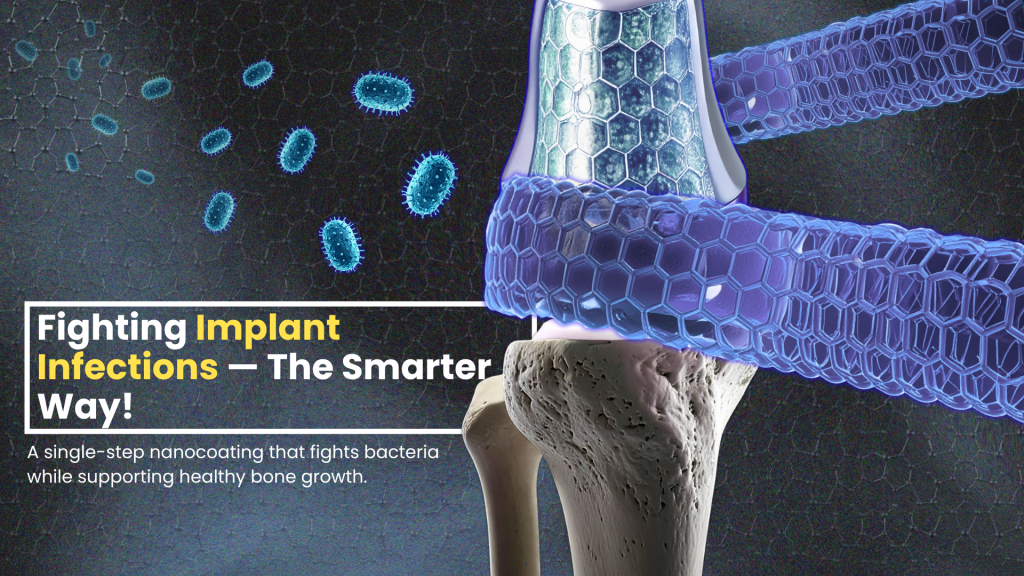

Biomedical implants, like artificial hip and knee joints, bone plates, and screws, are used to help people when their bones or joints are damaged. These devices are critical because they restore movement, correct bone problems, and improve the quality of life for patients, especially older people, accident victims, and those who suffer from bone-related diseases. Most implants are made of strong and safe materials, such as titanium alloys (like Ti6Al4V) and stainless steel. Titanium alloy (Ti6Al4V) is made of titanium (Ti), aluminium (Al), and vanadium (V). It is light, strong, and resists corrosion, which makes it suitable for permanent implants like hip and knee joints. Stainless steel (316L) is made mainly of iron (Fe), chromium (Cr), nickel (Ni), and molybdenum (Mo). It is tough, affordable, and often used for temporary implants such as bone plates, screws, and rods. But there’s a problem: germs (bacteria). Even though they are too small to see, bacteria can stick to the surface of implants and form biofilms. These biofilms protect bacteria and make infections very hard to treat. To stop implant-associated infections, scientists make special coatings and textures on implants. These coatings/textures must be antibacterial (able to kill harmful bacteria) or antifouling (prevent bacterial adhesion) and biocompatible (safe and non-toxic to human cells and tissues).

In this context, Ti–O–Zn-based nanocomposite coatings are very promising because titanium dioxide (TiO₂) is highly biocompatible, while zinc (Zn) is an essential trace element that also has strong antibacterial properties. Their integration into Ti-O-Zn phases combines these advantages, yielding coatings with synergistic antibacterial and biocompatible properties.

Researchers use different techniques to synthesize the Ti-O-Zn-based nanocomposite coating, such as plasma spraying, anodization, electrodeposition, chemical bath deposition, etc. But they all have drawbacks. An additional post-annealing step or high substrate temperature is required in most Ti-O-Zn-based coatings. As the Ti6Al4V substrate has microstructural stability and suitable mechanical performance up to a temperature of 400 ◦C, one of the aims of this study was to eliminate the post-annealing step. The goal is to synthesize Ti–O–Zn coatings in one process step, at low temperatures.

In a previous experiment, the authors had studied the influence of TiO2-ZnO composite film on enhancing the biocompatibility of stainless-steel surface. Radio-frequency magnetron sputtering (RF-MS) was used to synthesise TiO2-ZnO films. It was found that the TiO2-ZnO target with a chemical composition of 90:10 by weight percent yielded better biocompatible films with antibacterial properties. Another advanced method is magnetron co-sputtering, in which titanium (Ti) and zinc (Zn) are deposited onto the implant surface in the presence of oxygen (O). This technique can be carried out at low temperatures, which is essential to maintain the stability of the implant material. Hence, in this study, a ZnTiO₃-based nanocomposite coating was synthesized on Ti6Al4V substrates using a single-step, low-temperature reactive magnetron co-sputtering process with pure titanium and zinc targets in an Ar:O₂ (argon–oxygen) environment. Researchers then tested how well this coating worked against bacteria like Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli). The results were excellent, demonstrating antibacterial efficiency of approximately 97% against S. aureus and 99% against E. coli. Additionally, it showed better biocompatibility compared to the uncoated titanium alloy.

Hence, Ti-O-Zn-based coating can protect implants from infections and also support healthy bone growth, making implants safer and longer-lasting.

The following are the authors of the paper:

- Ms. Gimmi Guruprasad Engoor from the Department of Applied Mechanics and Biomedical Engineering, Indian Institute of Technology (IIT) Madras, Chennai, India.

- Ms. Sowmya Selvaraj from the Department of Biotechnology, Bhupat and Jyoti Mehta School of Biosciences, Indian Institute of Technology (IIT) Madras, Chennai, India.

- Prof. Vignesh Muthuvijayan from the Department of Biotechnology, Bhupat and Jyoti Mehta School of Biosciences, Indian Institute of Technology (IIT) Madras, Chennai, India.

- Prof. Satyesh Kumar Yadav from the Department of Metallurgical and Materials Engineering, Indian Institute of Technology (IIT) Madras, Chennai, India.

- Prof. Sujatha Narayanan Unni from the Department of Applied Mechanics and Biomedical Engineering, Indian Institute of Technology (IIT) Madras, Chennai, India.

- Prof. Nilesh Jayantilal Vasa from the Department of Engineering Design, Indian Institute of Technology (IIT) Madras, Chennai, India.

Dr. Murukeshan Vadakke Matham, Director of the Centre for Optical & Laser Engineering (COLE), Deputy Dirtector of The Photonics Institute, and Associate Professor of the School of Mechanical and Aerospace Engineering, at Nanyang Techniological University, Singapore, acknowledged the significance of the work done by the authors with the following comments: “Surfaces of many implants are susceptible to the adhesion of bacteria and subsequent biofilm formation. Hence, biocompatible and antifouling thin films on such implant substrates offer an alternative to conventional antibiotic coatings to combat antimicrobial resistance (AMR) and biofilm-related infections. The significance and relevance of the IIT Madras research team’s works on TiO2–ZnO composite thin films come in this context. The study they have conducted on the synthesis and characterization of TiO2–ZnO composite thin films is highly commendable. They could make the antibacterial and biocompatible ZnTiO3-ZnO nanocomposite coating on Ti6Al4V substrates by a single-step, low-temperature (200 ◦C) synthesis route using reactive magnetron co-sputtering of pure Titanium (Ti) and Zinc (Zn) targets in an Ar:O2 environment. It is envisaged that their findings can lead to the realisation of controlled bacterial adhesion and biofilm formation with potential biomedical applications in the near future. I wish the IIT Madras research team all success in taking this research further.”

Article by Akshay Anantharaman

Click here for the original link to the paper