With more than 6,000 human-made satellites orbiting in space, there is a need to come up with more innovative ways to reduce costs, and to launch smaller ones into space.

Small satellites are fast becoming popular and find uses in remote sensing, in communications such as to provide internet connectivity, for scientific research, etc. The advantages of small satellites are that they require reduced cost, are more flexible, and are faster to develop. Electric propulsion is a technology aimed at achieving thrust with high exhaust velocities, which results in a reduction in the amount of propellant required for a given space mission or application compared to other conventional propulsion methods. Reduced propellant mass can significantly decrease the launch mass of a spacecraft or satellite, leading to lower costs from the use of smaller launch vehicles to deliver a desired mass into a given orbit or to a deep-space target. In general, electric propulsion (EP) encompasses any propulsion technology in which electricity is used to increase the propellant exhaust velocity. This type of propulsion can lead to high exhaust velocities, resulting in better mass utilization efficiency for spacecraft. However, small satellites require a proper thrust, but with lesser power. Some of the candidates for small satellite applications are Ion Thrusters, Hall effect Thrusters, Pulsed plasma thrusters, Field emission Electric propulsion thrusters, Electrojet thrusters etc. Among these thrusters Pulsed Plasma Thrusters (PPTs) are a compelling option for electric propulsion in small satellites due to their simplicity, low power requirements, potential for long life, fine impulse control, suitability for low thrust manuevers etc particularly when using solid propellants like PTFE. While other electric propulsion systems like Hall thrusters and ion engines offer higher specific impulse, PPTs excel in situations where simplicity, low power, and reliability are crucial, such as attitude control and orbital maintenance of small spacecraft Pulsed plasma thrusters (PPTs). PPTs are a manifestation of electromagnetic propulsion a subcategory of electric propulsion where electric and magnetic forces act on a propellant. PPTs operate through short bursts of power; that way, the thruster can draw low steady-state power from a spacecraft while delivering high efficiency as a result of the high instantaneous power. They provide a straightforward, lightweight, compact, and high-performance propulsion solution for power-limited small satellites. They also feature low average power consumption and minimised heat generation making them well-suited for these applications. PPTs are well-suited for relatively small spacecraft with a mass of less than 100kg for roles such as attitude control, station keeping, de-orbiting manoeuvres and deep space exploration. Moreover, electric propulsion systems like PPTs contribute towards green energy initiatives in space technology by replacing traditional chemical-based propulsion with cleaner, electrically driven alternatives. The same technology could be adopted in the development of compact and energy-efficient water purification systems.

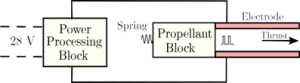

Fig. 1. Block diagram of a typical pulse plasma thruster (PPT).

Fig. 1 shows a block diagram of the PPT. When a high voltage (HV) is applied across the two electrodes, it initiates an arc that heats and decomposes the Teflon propellant into ionised plasma (a state of matter where a gas is energised such that its atoms lose electrons), which is then accelerated by the Lorentz force (force experienced by a charged particle when it moves through an electric or magnetic field) to produce thrust. The “Power Processing Block” is what provides electrical power supply to the PPT and is the critical component. This transition to electrically powered propulsion aligns with the broader global mission to promote green energy solutions in both terrestrial and space-based systems.

The challenge here is that the power processing block should prioritise cost-effectiveness and compactness, while also featuring high power density and efficiency with low average power consumption. But the utilisation of a non-pulsed HV power supply increases the average power rating and size of the supply which is impractical for small satellites. However, pulse power supplies fulfil the requirement of the power processing block, making them suitable for use.

Converter topologies often incorporate HV switches alongside pre-charging configurations to generate the necessary pulse profile. The usual pre-charging setups to deliver pulse power supply to PPTs usually have the drawbacks that they have longer charging time constants, and this affects two factors – pulse repetitive rate (PRR) and the full width at half maximum (FWHM) of the pulse power supply.

PRR refers to the number of pulses generated per second in a pulsed system, and FWHM refers to the measure of the width of a peak or pulse in a graph or signal. Longer charging time results in a reduced PRR, which also affects the FWHM. Hence, an alternative is required.

The literature so far has seldom focused upon converters achieving soft switching during pulsing. In this study, the authors Mr. Chinara Kuldip and Dr. Lakshmi Narasamma N from the Department of Electrical Engineering, Indian Institute of Technology (IIT) Madras, Chennai, India, have proposed a resonant flyback topology featuring a compact structure with reduced component count, galvanic isolation, higher PRR, and less FWHM, meeting the requirements of the PPT. This proposed application targets a low-power scenario and demands a short high voltage unidirectional pulse. It demonstrates an efficiency of over 90% for low-power applications.

Due to the large secondary turns and winding arrangements in the low voltage transformer (LVT) and high voltage transformer (HVT) of this application, the leakage inductance and the winding capacitance of the transformers increase. Leakage Inductance and Winding capacitance are known as the parasitics and must be taken into consideration as these factors significantly impact the performance of the application. Therefore, an energy-based analysis of the application was found to be necessary.

The proposed energy-based model and predictive control algorithm that has been accomplished was verified experimentally for a pulsed output voltage of -2.5 kV (kilo Volts), with the PRR restricted to 1 kHz (kilo Hertz) and the FWHM limited to 20 μs (micro seconds). The proposed approach improves the efficiency, reduces the cost, and simplifies the converter design.

Overall, this work not only improves satellite propulsion efficiency but also advances the adoption of clean and green energy in the aerospace sector and also could be extended for water treatment applications.

Dr. Dragan Maksimovic, Distinguished Professor from the Department of Electrical, Computer and Energy Engineering, University of Colorado, Colorado, USA, gave his analysis of the work done by the authors and acknowledged its importance with the following comments: “This paper presents a novel energy-based analysis and control methodology for a high-voltage pulsed power converter, an essential component in wastewater treatment systems based on ozone generation. The authors successfully demonstrate how a flyback converter, combined with a resonant post-processing stage, can efficiently generate programmable high-voltage pulses from a low-voltage battery source. The key innovation lies in quantifying and managing energy exchanges, including losses due to parasitic elements, using closed-form expressions, which simplifies the design and control processes and improves overall performance. The approach is validated through convincing experimental results. This work contributes significantly to the development of compact and energy-efficient water purification systems.”

Article by Akshay Anantharaman

Click here for the original link to the paper