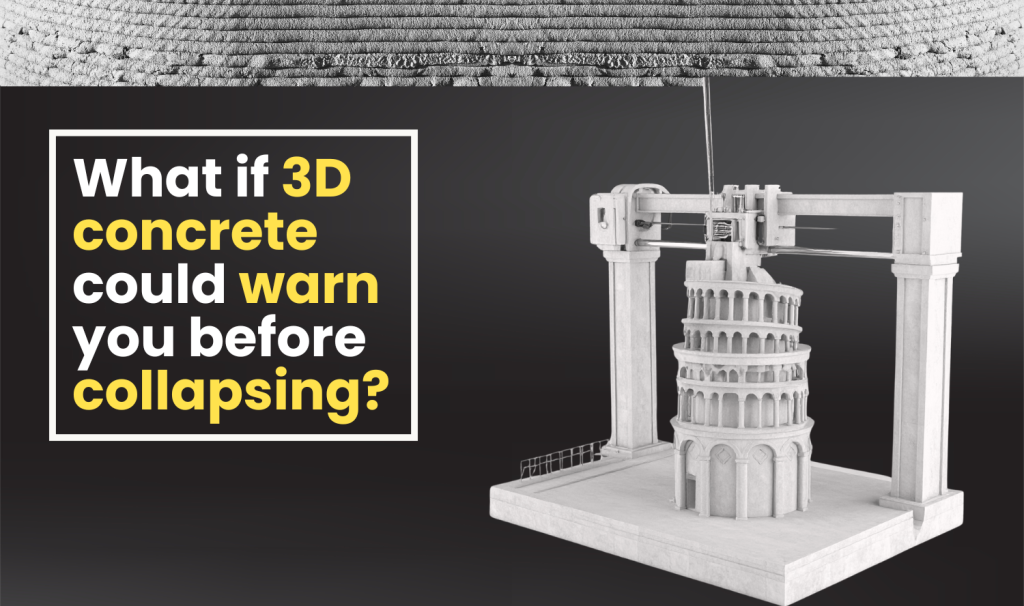

Concrete is the most widely used building material in the world. This is because of its properties such as high durability, superior fire resistance, and long service life. However, it requires more labour, and takes more time for construction.

There is therefore a need for a better way to produce concrete. 3D printing, also known as additive manufacturing, has been a Godsend for the manufacturing industry. The benefits of 3D printing include reduced manufacturing costs, improved product quality, lightweight construction, and the ability to produce complex geometries with high precision and accuracy.

With such advantages, it is good to know that concrete can also be printed using 3D printing techniques. Concrete three-dimensional printing (3DCP) is a digital technology that has the ability to overcome challenges and enhance automation in the construction industry. It can help print complex geometry shapes without formwork, and reduce labour and overall material used.

However, 3DCP does have some drawbacks. Despite significant research on the material properties of 3DCP, the practical application of the technology relies on heuristic calibration of input parameters like extrusion speed, printing speed, etc. Since it relies on extruding relatively thin layers of concrete, any minor defects or changes affect the dimensional stability of the 3D printed elements, leading to high variability in output quality.

Therefore, quality monitoring and control are of prime importance in this additive manufacturing. An autonomous system is required that can monitor and assess the quality of the printed elements.

Buildability and extrudability are the two main factors that affect the printing process according to researchers. Buildability refers to the ability of the individual layers of the concrete to hold their own weight and the weight of the layers printed above it without significant changes in dimensions. Many studies have found a printable region (workability range) within which the buildability and extrudability factors are satisfied. However, they use manual fresh-state tests, making it difficult to use in real-time.

Real-time monitoring of workability properties over time during printing is necessary to understand the buildability aspects. To achieve complete automation, a real-time monitoring and control system during the printing process is essential.

In this study, the authors Mr. Shanmugaraj Senthilnathan, and Dr. Benny Raphael from the Department of Civil Engineering, Indian Institute of Technology (IIT) Madras, Chennai, India, have proposed a real-time quality monitoring and assessment system, with a new metric called entropy standard deviation (ESD), using a simple 2D vision camera with computer vision (CV) techniques. The aim of this study was to develop a nonintrusive, autonomous, and continuous quality monitoring and assessment system to assess the buildability collapse of 3D printed elements.

The principal idea in this research is that surface texture changes of each individual layer can be quantified using CV techniques. Changes in the texture of individual layers indicate dimensional changes, and large variations might lead to buildability collapse. 2D images are collected after printing every layer using a camera placed in front of the printed specimen.

ESD has been introduced in order to quantify the dimensional changes for changes in the surface texture value. The 2D vision camera used was simple and cheap in cost. Computer vision (CV) is gaining prominence in the civil engineering industry for monitoring and inspections applications, and hence has been used in this study.

This is the first study to introduce a real-time, nonintrusive methodology to assess the dimensional changes during the printing process. Also, buildability collapse is predicted much before the collapse happens, giving sufficient time for corrective action to be taken. Future studies could use this technology for sustainable large-scale construction technology.

Dr. Bharadwaj Ram Kumar Mantha, who is an Assistant Professor at University of Sharjah, Sharjah, United Arab Emirates, and is also a Post Doctoral Researcher at New York University Abu Dhabi, Abu Dhabi, United Arab Emirates, acknowledged the importance of the authors’ work and its significance with the following comments: “Although three dimensional printing (3DP) has been implemented extensively in many fields and industries, its penetration into the construction industry remains less than optimal, and its applications are still limited due to several challenges. This study directly and indirectly addresses a few key challenges including that of rework through a novel computer vision based non intrusive and near real time prediction of buildability failure in 3DP concrete elements. One of the key highlights of this work is the newly developed, tested, and validated metric of entropy standard deviation (ESD). Unlike the typical studies, remarkable results with almost 100% prediction accuracy subject to certain preconditioning were observed. The study is especially timely given the growing relevance of 3DP in India and around the globe. For e.g., the affordable housing crisis in India and Dubai’s strategic goal to 3D print 25% of its buildings by 2030. The findings pave the way for more sustainable and scalable deployment of concrete 3DP in construction a.k.a 3DCP.”

Article by Akshay Anantharaman

Click here for the original link to the paper